How to get a guitar TV YELLOW

In this article we will detail step by step everything you need to know to get this type of finish on your guitar.

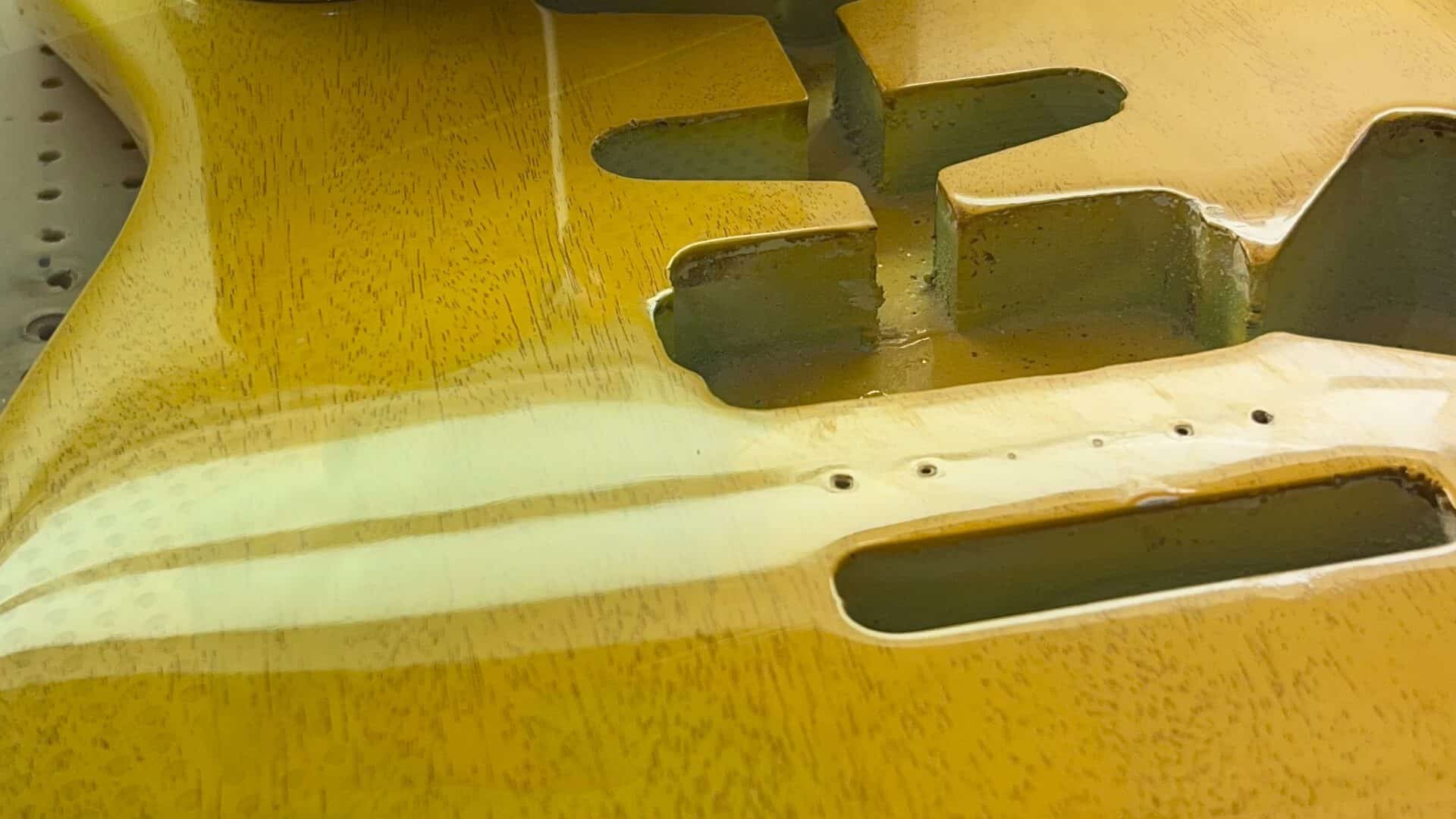

We will start with a mahogany body, an open pore wood, which we will highlight and take advantage of to give that characteristic touch in this type of finish.

What products will we need for the process?

- GRAIN FILLER

- PRIMER WHITE

- COLOR TV YELLOW

- LACQUER GLOSS

- LIJAS

- POLISH COMPOUD CUT + SUPERFINISH (OPTIONALS)

PHASE 1: Base coat and sanding

In this phase we will take the wood from scratch. If this wood does not have any damage it will not be necessary to sand it before starting to apply the primer.

- We begin to apply the white base coat in thin layers. The objective of this process is not to apply layers until the pore of the wood is completely covered, but to give a white base coat that affects the final tone of the guitar, and at the same time acts as a base.

- Therefore, 2 or 3 thin layers should be sufficient to achieve this objective.

PHASE 2: We mark the grain of the wood with Grain Filler.

In this phase we will apply the Grain filler on top of the white background. This product will serve to fill the pores and thus facilitate the application of paint later and also mark them giving a characteristic visual effect in this type of process.

As the color that we will use later is a translucent color, the pores of the wood will be visible once we apply all the layers of color and transparent varnish.

The process will consist of the following:

- Mix the product with water and stir until it dissolves a little and becomes a viscous paste.

- Once we have this paste, we will apply it all over the surface by means of a cloth or a brush until covering all the wood.

- Let dry for 2-3 minutes and begin to remove with a cloth. It is important not to exceed this time, since although the Grain Filler is a water-based product, which should be easily removed, if it dries it can be more expensive to remove..

- Repeat the process if during the removal the pores of the wood are not sufficiently marked.

PHASE 3: Apply the color Tv Yellow

The following steps are recommended for color application:

- Apply the color in thin layers at 20 cm distance.

- The layers must be thin and must be left between them for at least 12 hours, so that the solvent of the nitrocellulose can evaporate and thus obtain hardness on the surface.

- Between coats sand with P800 grit, to eliminate irregularities if any.

As we apply different layers the shade will become more and more intense. In our experience, the correct shade is reached at the end of the fourth coat.

However, it may vary according to the amount of product applied in each layer, and of course it will depend on the final tone that each person wants to give to their guitar.

PHASE 4: Application of finish and sanding

As a last mandatory phase we will have the application of the finish. In our case we have used Golden Age, which will match the vintage effect of this guitar model, typical of the 60s.

However the type of finishing varnish may vary, depending on the result that each customer wants to obtain.

- Do 3 coats leaving to dry at least 12 hours between them.

- Once the finish coats have completely dried, we will do a complete sanding process.

- Wet the surface and begin sanding with P1000, P1500, P2000 and finish with P3000. With this we will leave the surface as smooth as possible, and ready to polish in case we opt for this step.

PHASE 5: Polishing (optional)

This step is recommended to be omitted if you have used a matte finish, as there will be hardly any improvement in the final result.

On the other hand, if you have used a glossy finish, with this process you can achieve a noticeable change in the final finish.

This will eliminate small scratches that may have been left after sanding, and will significantly enhance the final brightness.

The polishing process consists of 2 phases and products, which must be combined if you want to obtain a good result.

To do this you must follow these steps:

- Shake the polish can vigorously COMPOUD CUT and apply to the surface. We polish with the white cutting sponge. It is important not to exceed in time so as not to overheat the nitrocellulose on the surface and damage it.

- We repeat the process with the product of the second phase: SUPERFINISH. For this product we must use the black polishing sponge.

- Wipe off any remaining polish residue with a cloth and Polish & Cleaner.